The process uses a bonding agent to join two or more flexible packaging webs, the webs are made of films, aluminium foils and papers. Different technologies cover a variety of applications in flexible packaging. The lamination process not only protects the product but also extends the shelf life. Lamination for flexible packaging can be broadly divided into wet lamination, dry lamination, solvent lamination and wax lamination.

Lamination capabilities include:

- Solventless, solvent base and water-based lamination processes.

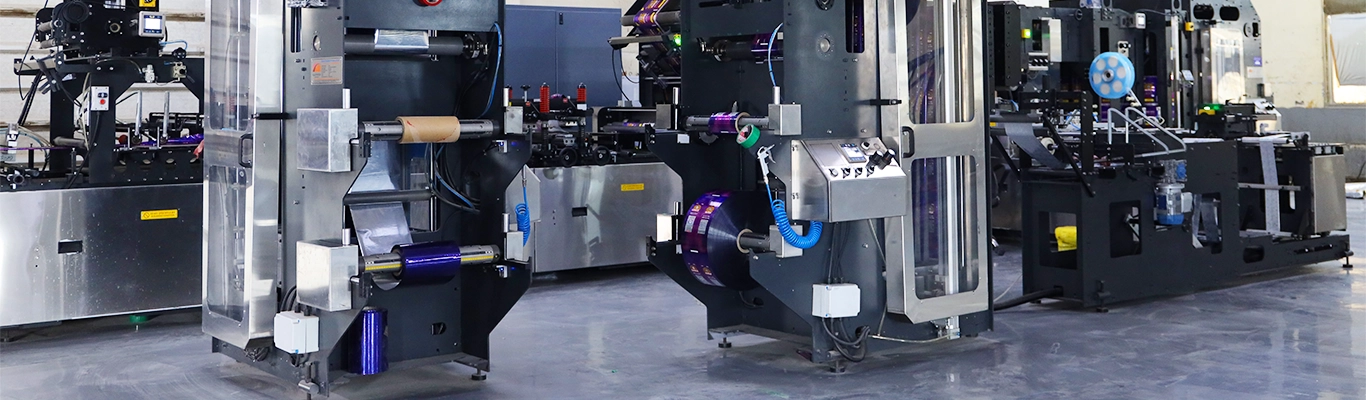

- The most combo process machine of Nordmeccanica.

- A solvent/water-based or solventless lamination is used to combine two or more layers.

- The adhesive can perform additional functions, such as resistance to chemical migration, maintaining bonds during high-temperature processing, and combining layers without adding bulk and barrier.

Our standard laminates are composite materials made from LLDPE that form the core barrier of the tube body. They help keep contents fresh and safe with multiple layers of foil.

- Standard laminates of LLDPE, foil, CPP, and Polyester are primarily used in the food industry.

- Poly-coating extrusion Lamination

- Special laminates: End-to-end from development, and testing to commercial production

- Custom web structures development: Aluminium Barrier Laminate [ABL], custom-coloured plastic laminates, holographic laminates etc as per application.

Aluminium Barrier Laminates (ABL) allow superior light, air and moisture barrier along with reduced flavour absorption in a more durable tube; suitable for pastes, ointments, creams, gels, etc.

Plastic Barrier Laminates (PBL) are particularly suitable for packaging that needs to offer strong chemical resistance whilst maintaining barrier properties. Standard laminates are offered in white or natural (clear), but speciality custom colours can also be developed.

(One high-speed dry lamination {U-Flex} and four wet lamination {Narendra Make} )

(5 Solvent-less Lamination)

(Two Extrusion Lamination {Fongkee and Raju Kohli Make} for high speed and specialised laminates)